Clean Room Facility

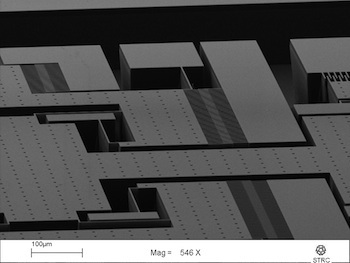

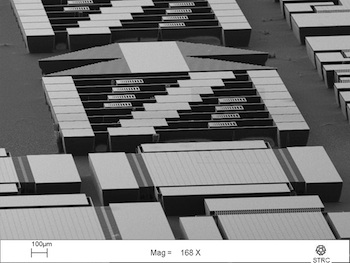

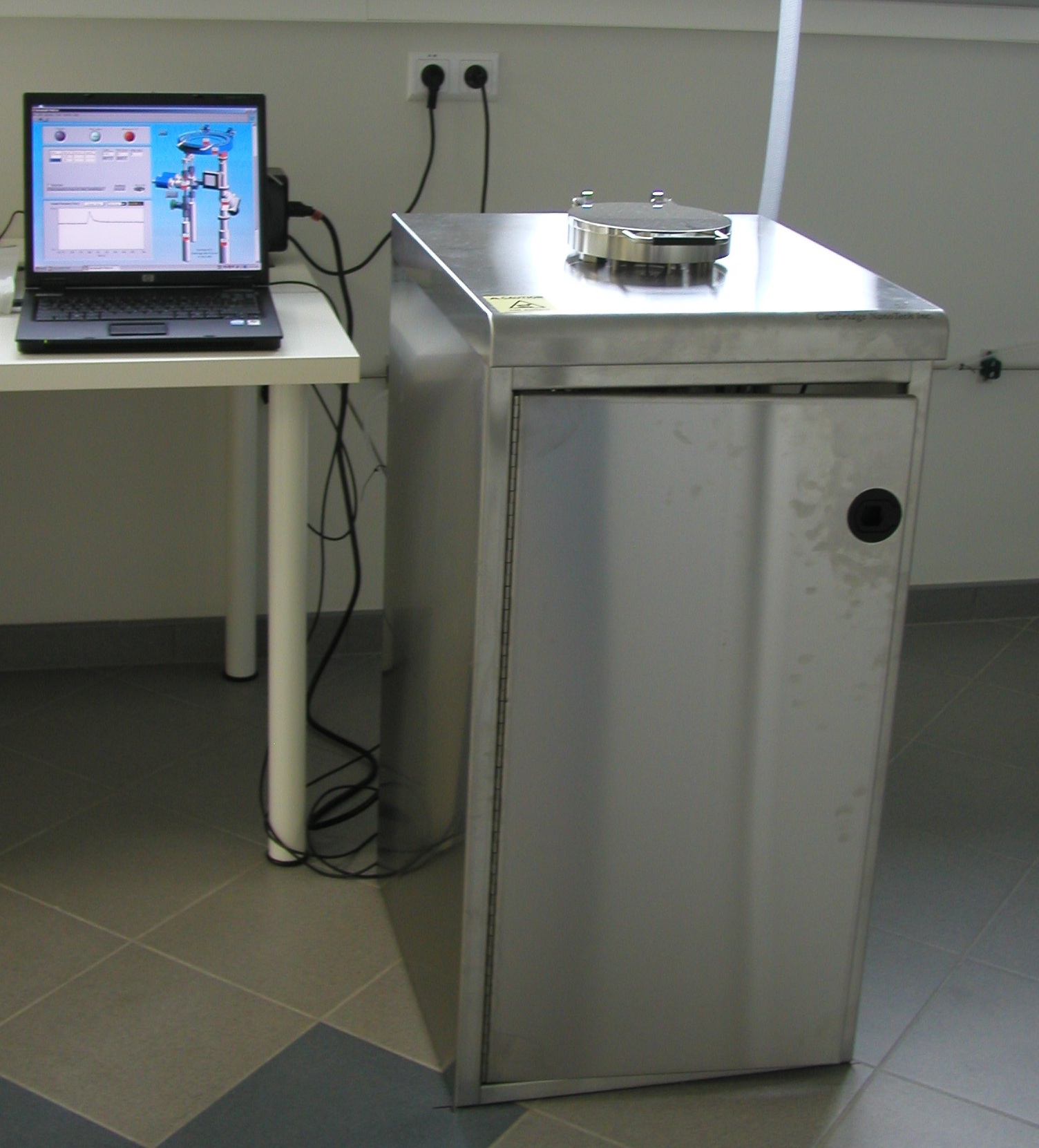

The Clean Room lies at the heart of the research facilities at the Yousef Jameel Science and Technology Research Center. Inside the cleanroom are state-of-the-art facilities for developing MEMS/NEMS devices. This includes the Cryogenic Deep Reactive Ion Etcher (Cryo DRIE), capable of etching deep trenches with a high aspect ratio (up to 1:50). The Plasma Enhanced Chemical Vapor Deposition system (PECVD) is also available in the cleanroom for depositing low-stress thin films of various materials such as SiN, SiO2, SiC, doped, and undoped SiGe. Lithography facilities that include the EVG620 Mask Aligner, Spinner, and Wet Bench are also important parts of the cleanroom facilities. Other facilities include Tousimis Critical Point Drier, Wafer Geometry Gauge, and Surface Profiler.

For AUC internal user access requests, click here.