Process Safety and Control Lab

In this lab, researchers, investigators, and users can conduct experiments on energy losses, dynamic head measurements, flow over weirs of different shapes, flow over a cavity, fixed and fluidized bed experiments, solids handling and sedimentation studies, and flow through porous media. Different process control systems such as level, flow, pressure, temperature, speed, and position can be investigated.

To measure the pressure drops generated in a pipe for different flow rates and both laminar and turbulent conditions.

Experiments/Tests:

- Investigate the head loss due to friction in the flow of water through a pipe and determine the associated friction factor over a range of flow rates in laminar flow

- Investigate the head loss due to friction in the flow of water through a pipe and determine the associated friction factor over a range of flow rates in turbulent flow

- Determine the critical Reynolds number

To demonstrate the operation and characteristics of a Pitot-static tube that is used to determine fluid velocity by measuring the difference between the total head and the static head of water flowing inside a pipe using a manometer.

Experiments/Tests:

- Exercise 1 - Operation of a Pitot-static tube

- Exercise 2 - Converting Dynamic head measurements to fluid velocity

- Exercise 3 - Determination of developed Dynamic head profile in a pipe

- Exercise 4 - Determination of undeveloped Dynamic head profile at the entrance to a pipe after a bend

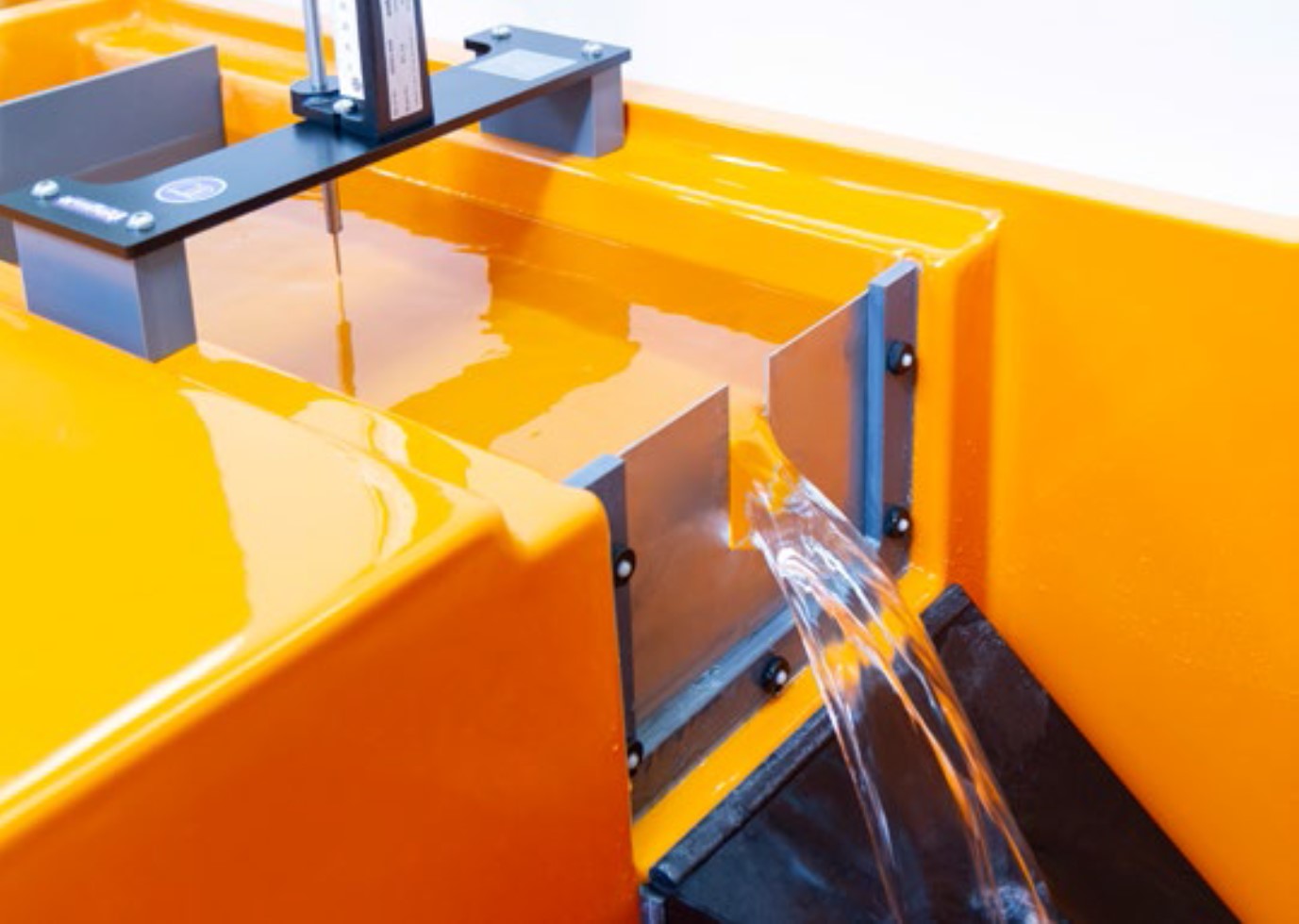

To determine the characteristics of flow over rectangular and triangular weirs.

Experiments/Tests:

- Determine the characteristics of open channel flow over a rectangular notch

- Determine the characteristics of open channel flow over a triangular (V) notch

- Determine values of the discharge coefficient for both notches

This unit demonstrates to users visually, audibly, and numerically the phenomenon of cavitation and its association with the vapor pressure of a liquid.

Experiments/Tests:

- Demonstrate the appearance and sound of Cavitation in a hydraulic system

- Demonstrate the conditions for Cavitation to occur (liquid at its vapor pressure)

- Observe the difference between air release from the water and true Cavitation

- Show how Cavitation can be prevented by raising the static pressure of a liquid above its vapor pressure

- Verification of Bernoulli’s equation

- Comparison of theoretical and actual pressure at cavitation conditions

To support a comprehensive range of hydraulic models, each of which is designed to demonstrate a particular aspect of the hydraulic theory.

To learn the fundamentals of flow through fixed beds and fluidized beds.

Experiments/Tests:

- Learning the fundamentals of flow through fixed beds and fluidized beds (Darcy)

- Observation of the fluidization process

- Pressure loss is dependent on the flow rate, type, particle size and height of the bulk solid

- Determination of the fluidization velocity and comparison with theoretically calculated values

- Verification of Carman-Kozeny equation

To study the basic physical processes involved in sedimentation.

Experiments/Tests:

- Effect of initial concentration on sedimentation rates

- Construction of settling-rate curves from a single batch test

- Effect of initial suspension height on sedimentation rates

- Effect of particle size distribution

- Use of flocculating additive

To study the behavior of granular materials.

Experiments/Tests:

Solids handling

- Reducing the size of granular material using a ball mill (comminution)

- Dry blending using a ball mill

- To examine the efficiency of mixing granular materials (powder to powder) in a Vee blender

Powder handling

- Measuring bulk density, particle density and porosity (voidage) of granular materials

- To determine the bulk density of various solids and to examine the influence of moisture content and compaction of the bulk density

- To determine the natural angle of repose for a variety of materials using a Hele-Shaw cell and to examine the influence of moisture content on the repose angle

- To observe the natural stratification and agglomeration of various materials using a Hele-Shaw cell

- To investigate how the discharge (flow) rate of solids from a hopper is related to the diameter of the issuing orifice and whether the head of material over the orifice has any effect on the flow rate

- To demonstrate the operation of a pneumatic conveying system for solids and to show how a cyclone is used to separate the solids from the air stream

Sieve Analysis

- To determine and analyze the size distribution of a fixed granular solid by using a test sieve stack and a vibratory shaker

To facilitate the study of flow through fixed and fluidized beds of solid particles.

Experiments/Tests:

- Exercise 1 - Determining the Voidage of granular material

- Exercise 2 – Flow through Fixed and Fluidized beds using water as the fluidizing medium

- Exercise 3 – Flow through Fixed and Fluidized beds using air as the fluidizing medium

- Exercise 4 – Comparison of Granule size using air as the fluidizing medium

- Exercise 5 - Demonstration of Liquefaction of solids (Quicksand and similar phenomena)

To demonstrate the application of Darcy’s Law of Filtration and the principles of batch filtration using a fully functional plate and frame filter system.

Experiments/Tests:

- Exercise 1 - Filter Assembly and Valve Sequencing

- Exercise 2 - Demonstration of Precoat Filtration

- Exercise 3 - Optimization of Filtration Performance Using Body Aid

- Exercise 4 - Demonstration of Darcy's Law

- Exercise 5 - Determination of Medium and Cake Resistances

- Exercise 6 - Effect of Body Aid on Medium and Cake Resistances

- Exercise 7 - Filter Cake Washing and Dewatering

- Exercise 8 - Economic Optimization of Filtration Operations

- Exercise 9 - Determination of Clean Membrane Resistance

This unit offers basic experiments on a level-controlled system with integral action.

This unit offers basic experiments on a flow-controlled system with integral action.

This unit offers basic experiments on a pressure-controlled system with integral action.

This unit offers basic experiments on a temperature-controlled system with integral action.

This unit offers basic experiments on a speed-controlled system with integral action.

This unit offers basic experiments on a position-controlled system with integral action.