Mass and Heat Transfer Laboratory

The thermal properties and performance of fluidized beds and different heat exchangers can be investigated. Different mass transfer-related measurements can be conducted, in this lab, such as gaseous and liquid mass transfer coefficients, cooling tower performance, liquid/liquid extraction measurements, gas absorption measurement, fixed-bed adsorption measurement, and crystallization phenomenon and kinetics measurements.

To investigate various non-metallic building materials with regard to their thermal conductivity.

Experiments/Tests:

- Determine the thermal conductivity k of different materials

- Determine the thermal resistance

- Determine thermal conductivity k for several samples connected in series (up to a thickness of 50mm)

To study the effect of different fluids on heat conduction.

Experiments/Tests:

- Generate a temperature difference familiarization with the device (test fluid: Air)

- Calculating thermal conductivity and thermal resistance (Test Fluid: Gas)

- Fundamental understanding of the cooling process

- Variation of the test fluid (suggestion: water) Comparison of measured values to experiment 2

- Steady behavior, block capacity Calculating the cooling process in air

- Transient behavior, block capacity with water

To demonstrate the application of the Fourier rate equation to simple steady-state conduction linearly through the wall of a tube.

Experiments/Tests:

- Determine the rate of heat flow through solid materials

- Measure the temperature distribution for steady-state conduction of energy through a uniform plane wall and a composite plane wall

- Determine the overall heat transfer coefficient for differing materials in a series

- Determine thermal conductivity k of different materials (conductors and insulators)

- Determine the relationship of a temperature gradient to the cross-sectional area

- Determine the effect of contact resistance on thermal conduction

- Understand the application of poor conductors (insulators)

- Observe unsteady-state conduction (qualitative only)

This unit is used for training in the areas of thermodynamics, fluid mechanics, and heat transfer.

Experiments/Tests:

- Measure the pressure loss (depending on flow velocity and particle size of the bulk solid)

- Measure the Pressure Distribution in the Fluidized Bed

- Determine the Fluidization Velocity

- Measure Heat Transfer in the fluidized bed:

- influence of the airflow rate on the heat transfer

- influence of the heater position

- influence of the particle size

- Determination of the heat transfer coefficient

To understand the fundamental concepts of heat transfer and quickly assess heat transfer rates by forced convection.

Experiments/Tests:

Exercise 1: Water to Air Heat Transfer

Exercise 2: Energy Balance

Exercise 3: Effect of Water Flow Rate

Exercise 4: Effect of Inlet Water Temperature

Exercise 5: Overall Heat Transfer Coefficient (U)

Exercise 6: The effectiveness (ε)- To mathematically determine water and air output temperatures and compare them with those read from Exercise 5

To study heat transfer with either an external jacket or an internal coil under batch-wise or continuous feed conditions.

Experiments/Tests:

Exercise 1: Indirect Heating and Cooling

Exercise 2: Batch Heating Characteristics of a Stirred Vessel with Coil

Exercise 3: Batch Heating Characteristics of a Stirred Vessel with Jacket

Exercise 4: Overall Heat Transfer Coefficient

Exercise 5: Efficiency and Heat Transfer Coefficient with Coil

Exercise 6: Efficiency and Heat Transfer Coefficient with Jacket

Exercise 7: Effect of stirring on heat transfer characteristics

To study the operation of a small-scale heat exchanger system.

Experiments/Tests:

- Demonstration of indirect heating/cooling by transfer of heat from one fluid stream to another when separated by a solid wall

- Energy balance determination (heat balance) and calculation of efficiencies by measuring the flow rates and temperature changes in the hot and cold fluid streams

- Introduction to different types of heat exchangers and comparison of the differences in operation and performance

- Using the Logarithmic Mean Temperature Difference (LMTD) in heat transfer calculations

- Definition and measurement of Overall Heat Transfer Coefficient (U).

- Demonstration of the differences between counter-current and co-current operation (not relevant for some HT34 configurations)

- Demonstration of the transition from linear to turbulent flow

- Effect of hot and cold fluid flow rate on the heat transfer coefficient

- Effect of the driving force (temperature differential) on the heat transfer coefficient

- Investigation of heat loss and reduction in heat transfer coefficient due to fouling of the heat transfer surfaces (suitable student project using user-induced fouling)

To demonstrate the application of the Fourier rate equation to simple steady-state conduction radially through the wall of a tube.

Experiments/Tests:

- Understand the use of the Fourier rate equation in determining the rate of heat flow through solid materials

- Measure the temperature distribution for steady-state conduction of energy through the wall of a cylinder (radial energy flow)

- Determine the constant of proportionality (thermal conductivity k) of the disk material

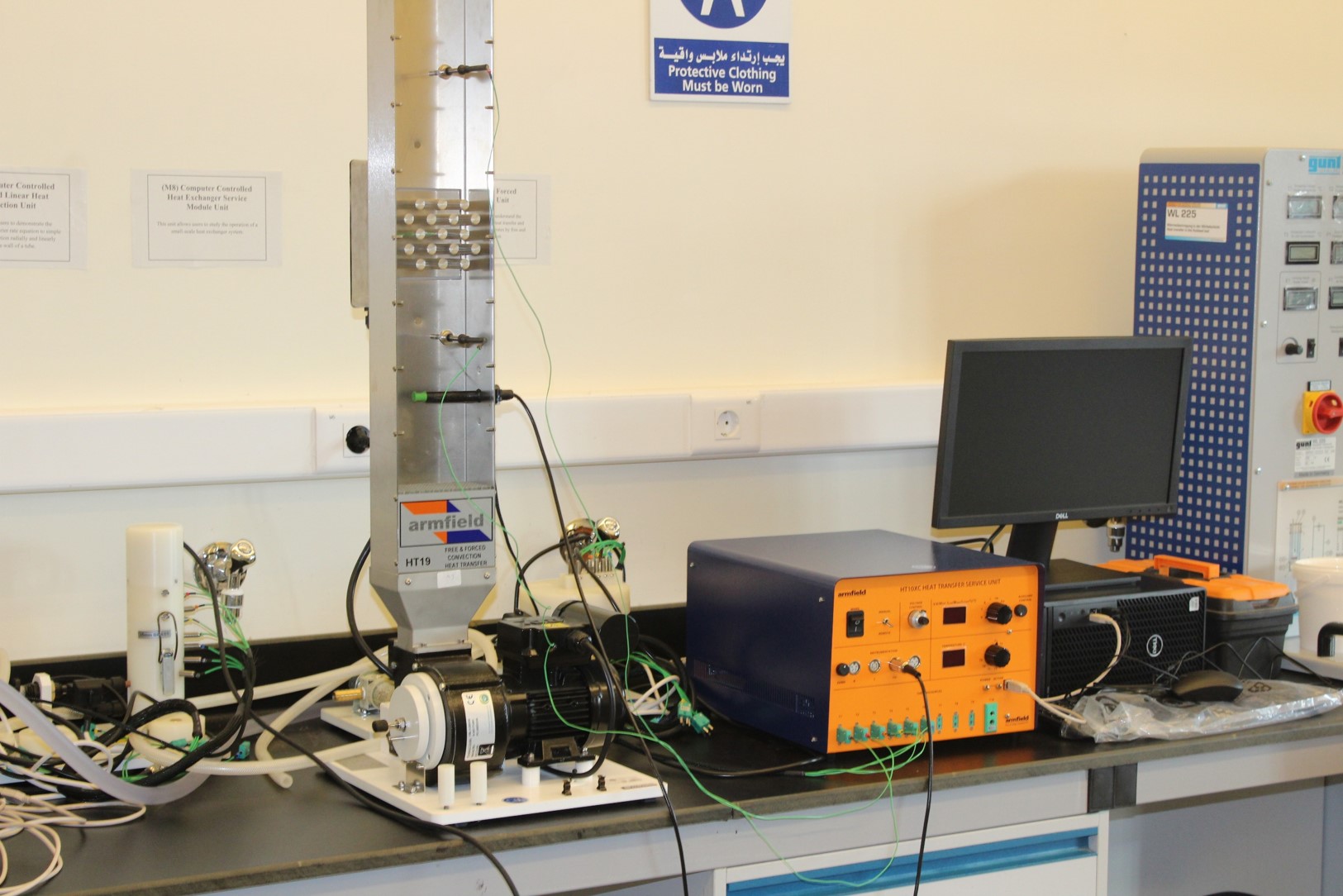

To understand the fundamental concepts of heat transfer and quickly assess heat transfer rates by free and forced convection

Experiments/ Tests:

Exercise 1: Power input and surface temperature in free convection

Exercise 2: Power input and surface temperature in forced convection

Exercise 3: Extended surfaces to improve heat transfer

Exercise 4: Temperature distribution along an extended surface

Exercise 5: Horizontal and vertical free convection on a flat plate

Exercise 6: Determination of the characteristic velocity and the Reynolds, Grashof and Rayleigh numbers for a flat plate in free convection

Exercise 7: Calculation of the average heat transfer coefficient of the pinned heater in forced convection

Exercise 8: Horizontal and vertical configurations for the finned heater in free convection

To measure a reasonable degree of accuracy of fluids diffusivity.

Experiments/Tests:

- To determine the diffusion coefficient of gas by evaporation from a liquid surface

- Direct measurement of mass transfer rates in the absence of convective effects

- Use of gas laws to calculate concentration differences in terms of partial pressures

- Use of Fick’s law to measure diffusion coefficients in the presence of a stationary gas

- Measurement of the effect of temperature on diffusion coefficients

- Investigation into diffusion coefficients of alternative fluids

- Gaining familiarity with the use of laboratory instruments to achieve accurate measurements of data required for industrial process design

Measurement of molecular diffusivities relating to an equimolar counter-diffusion process and in so doing familiarize students with the basic notions of mass transfer theory.

This unit is designed to give lab users an appreciation of the construction, design, and operational characteristics of a modern forced draught evaporative cooling system.

Experiments/Tests:

Exercise 1: Observation of the processes occurring within a forced draught cooling tower

Exercise 2: Effect of water inlet temperature on the performance of the cooling tower

Exercise 3: Effect of airflow on the performance of the cooling tower

Exercise 4: Effect of water flow rate on the performance of the cooling tower

Exercise 5: Effect of packing density on the performance of the cooling tower

Exercise 6: Effect of packing height on the performance of the cooling tower

Exercise 7: Performing a mass balance and a heat balance across the tower

To separate one or more of liquid components from a liquid mixture.

Experiments/Tests:

- Hydrodynamics of a packed liquid/liquid extraction column

- Differences in extraction performance using the organic phase or the aqueous phase as the continuous phase

- Investigation into the effect of changes in aqueous and organic flow rate

- Mass balances and the calculation of mass transfer coefficient

To demonstrate the process of gas absorption and stripping.

Experiments/Tests:

- Study of basic principles of the absorption of a gas into a liquid using a packed column

- Determination of loading and flooding points

- Study of hydrodynamic characteristics of a packed column

- Demonstration of physical and chemical absorption

- Investigation of the effectiveness of CO₂ absorption in pure water and in an aqueous solution

- Demonstration of gas desorption

- Determination of the mass transfer coefficient

This unit demonstrates the drying of solids by passing a stream of hot air over trays of wet material, a method commonly used in industry.

To demonstrate the principles of crystallization using batch cooling crystallization.

Experiments/Tests:

Exercise 1: Visual demonstration of crystallization phenomenon, mass and energy balances

Exercise 2: Evaluation of nucleation kinetics and the effect of the cooling rate

Exercise 3: Effect of agitation rate on MSZW (Metastable Zone Width)

Exercise 4: Determination of Crystal Size Distribution and Dominant Size

Exercise 5: Study of the continuous crystallization kinetics

To demonstrate the gas adsorption phenomenon using Fixed Bed Adsorption Column.

Experiments/Tests:

- Study of the adsorption/desorption processes under different operational conditions: temperature, flow rate, molar fraction and pressure

- Study of the breakthrough curves of temperature profiles during the adsorption/desorption process

- Study of the quasi-isothermal regime at low concentrations and pressures

- Study of the solute movement theory model, which describes the adsorption/desorption process

- Familiarization with the formation of the compressive and dispersive fronts in adsorption processes

- Analysis of the breakthrough curves of CO2 during the adsorption and desorption/regeneration processes

- Obtain the adsorption equilibrium isotherm of CO2 from the desorption curve (dispersive wave)